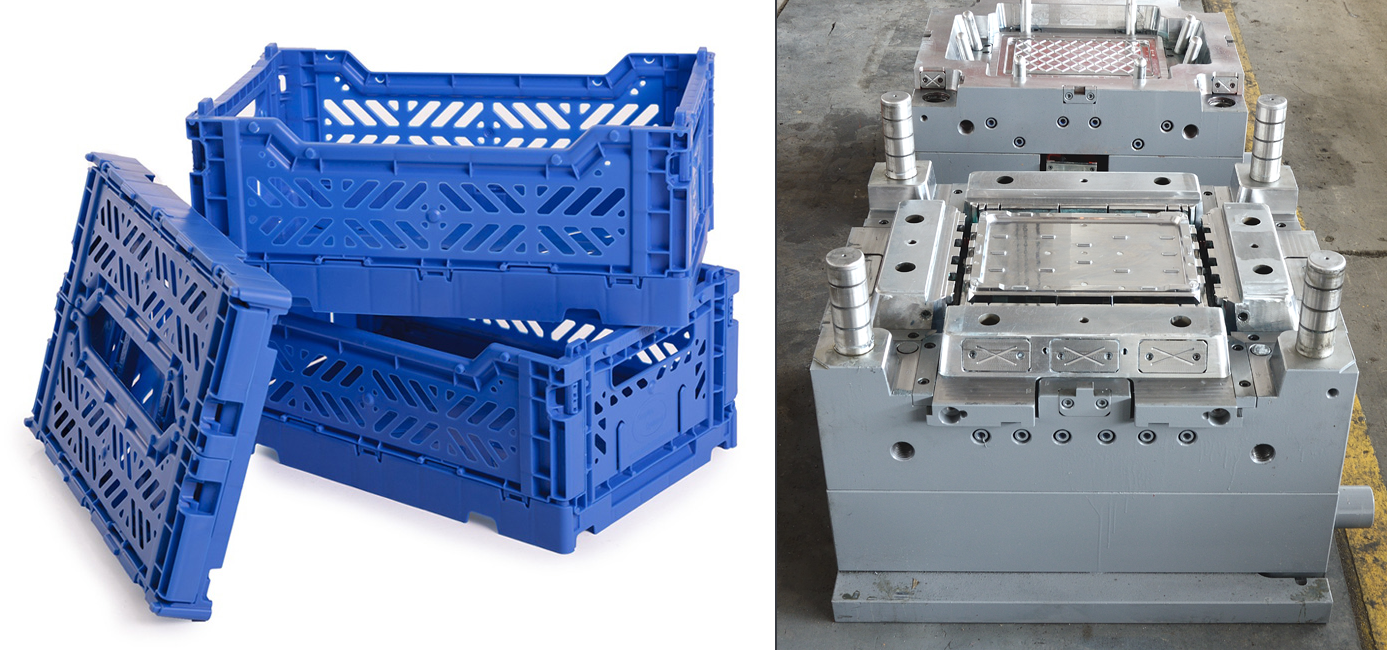

How to make a turnover box mold? The first thing to do is to choose the right steel material for the mold base and mold core cavity. For example: To produce a turnover box mold with one out of four, it is necessary to use pre-hardened steel materials with a hardness higher than 33 as the mold base, and then select suitable mold standard parts. Secondly, the hardness of each piece of steel must be well controlled, not too hard.

Then, the friction and guide parts of the crate mold must be finished without any manual work. If you need to injection mold a durable tote, you must use a low melt index HDPE material, such as an index 4 or 6 plastic.

Second, make sure the cooling system is at its optimum. To manufacture a durable and durable 2 hydraulic drive machines with the automatic ejection of the machine, the ejection action during mold opening can be smoother. For different types of molds, precise mold processing is required to ensure the accuracy of the mold operation, otherwise the mold cannot have high-speed operation performance, and the cooling water circuit design on the largest molding surface of the mold must be optimized.

Want high quality tote molds with fast cycle times? Contact us immediately, we will give you satisfactory molds and services.